The great debate – Lead came vs copper foil

Stained glass is a timeless art form used to decorate buildings for centuries. The colorful glass pieces allow light to stream through in dazzling patterns. But how exactly are these intricate works constructed?

There are two main techniques used in stained glass creation – lead came and copper foil. Both methods have been passed down through generations of artisans. In this post, I’ll take a deep dive into lead came versus copper foil. You’ll learn the key differences between these two traditional stained glass building styles. I’ll also look at whether you can blend the techniques and examine some alternatives.

By the end, you’ll have the knowledge to choose the ideal approach for your next stained glass project. Let’s get started!

What is Lead Came?

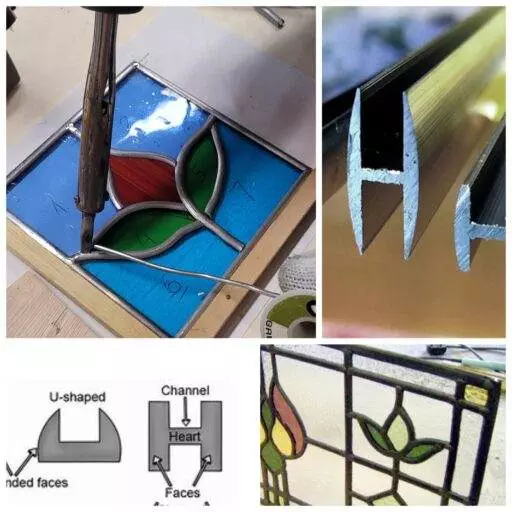

Lead came consists of thin strips of lead with an H-shaped or U-shaped cross section. The came strips create channels that hold the edges of the glass pieces.

To construct a lead came panel, first cut the glass pieces to fit the design. Then carefully place each piece into the came channels. Solder the joints where the came strips meet to fuse and strengthen the sections.

Once the entire panel is assembled, apply a final sealing putty. Putty waterproofs the window and prevents the glass from rattling. Lead came creates clean, sturdy lines and allows for intricate glass cuts. It’s an age-old, traditional technique perfected by medieval artisans.

What is Copper Foil?

Copper foil is an extremely thin, narrow and flexible strip of copper with an adhesive backing. In stained glass, copper foil tape is used to wrap the edges of the glass pieces. Once wrapped in foil, the glass pieces are then soldered together all along the foiled edges.

The use of copper foil in stained glass is largely credited to Louis Comfort Tiffany in the late 19th and early 20th centuries. This method (aka Tiffany copper foil method or just Tiffany method) revolutionized three dimensional projects like lampshades where small glass pieces and intricate curves wouldn’t allow the use of lead came.

The thin strips of copper foil allow for precise solder lines as well as the ability to create intricate and detailed designs. Instead of just connecting at intersections like lead came, the entire copper strip is fused. This enables light, delicate pieces to be combined into a cohesive work. The choice between lead came and copper foil impacts the entire building process.

Key Differences Between the Techniques

While both methods have long histories over generations, there are some vital differences between lead came and copper foil. Here are some of the main contrasts:

- Appearance – The H-shaped lead came creates uniform, sturdy lines. Copper foil allows for more fluid, sketch-like lines of varying widths.

- Durability – Lead came windows can stand up to weather when properly sealed. Copper foil is more prone to adhesive failure, especially outdoors.

- Strength – The rigidity of lead came carries weight better. Copper foil results in a more flexible overall piece.

- Learning curve – Copper foil is easier for beginners to pick up. Lead came requires more practice to master.

- Design – Lead came works best for geometric lines. Copper foil allows intricate shapes.

- Cost – Copper foil is generally more expensive due to intensive labor. Lead came uses less solder.

- History – Many major historical buildings contain leaded glass windows and panels. Copper foil originated in the late 1800s.

Can You Combine Copper Foil and Lead Came?

Maybe it’s not so much a question of lead came vs copper foil. An interesting (and maybe better) question is whether you can blend both lead came and copper foil in one window. The good news is that you can absolutely combine them!

Lead came is used to make up the majority of the structure of a panel, especially geometric panels. Copper foil is used for intricate sections and adding decorative touches. These foiled pieces are soldered first.

The foiled portion is treated as a single glass shape when fitting into the lead came matrix. This marries the durability of lead with the delicate flair that copper foil provides.

Are There Alternatives to Lead Came ?

While lead came is a tried and true choice, there are alternatives. Here are a few lead-free options:

- Zinc came – Offers similar aesthetics without the risks of lead. However, zinc is much harder to work.

- Brass came – Has an elegant look but requires expert soldering skills.

- Copper came – Expensive option with an eye-catching finish. Needs frequent polishing.

- U-channels or flat bars – Formed strips without lead. Require more reinforcement.

- Reinforced copper foil – Heavier gauge foil and additional soldering provides stability.

These alternatives sacrifice some benefits of lead. But they allow artists to adapt when lead isn’t suitable for health, structural, or preference reasons.

What’s the Difference Between Lead Came and Hobby Came?

Hobby came is a thinner form of lead came. It has a narrower profile designed for embellishing projects. Click here to watch a video short of how one crafter uses hobby came.

The channels in hobby came are shallower to only accommodate thinner glass. It can’t support large heavy pieces like standard lead came. Hobby came also takes more precision to cut and work with.

Due to its petite size, hobby came doesn’t require stretching. Its intent is decorative rather than structural. You’ll see it on sun catchers, small windows, or as accents in jewelry. Hobby came gives sparse but precise leading lines.

How Does Lead Came Differ from Copper Foil?

We’ve already touched on some core differences like appearance, flexibility, and learning curves. Here are a few more nuanced contrasts:

- Foil wraps each fragment separately while lead forms a continuous network.

- Foil allows unconventional shaped glass that is not possible (or at least extremely difficult) with lead channels.

- Lead came imparts an architectural feel. Foil has more of an artsy vibe.

- Glass is placed into the channels of the lead strips while foil is wrapped around the edges of the glass pieces.

- Foil is always soldered along entire seams. Lead is only soldered at intersections.

- Foil lines are built up with solder. Lead size depends on strip width alone.

The differences come down to the fundamentals of each method. Lead came joins a framework that glass rests within. Foil attaches the glass itself into a cohesive sheet.

Can You Use Copper and Lead Together?

As mentioned earlier, you can combine copper foil and lead within one work of art. In fact, many pieces benefit from the best of both worlds.

A simple design would have copper foil accent pieces set into lead came foundations. Or vice versa for a primarily foiled project with came structural supports. Stained glass artists can pick and choose techniques as desired.

Are Lead and Copper Compatible for Soldering?

Soldering is an essential part of stained glass assembly. The good news is lead and copper are fully compatible metals for soldering. This is why artisans can blend both came and foil without issue.

Typical stained glass solder consists of tin and lead. This alloy readily bonds with copper foil. Lead came is also easily solderable. There are no chemical barriers to combining these materials.

Is Lead Came Stronger Than Copper Foil?

When properly reinforced and sealed, lead came does provide a stronger finished product. The continuous strips offer robust structure against gravity and weather.

Copper foil relies solely on fused seams for strength. For large pieces or outdoor exposure, copper foil requires very precise soldering along every inch. Foiled works also benefit from additional structural supports. Support strips soldered across panels add strength.

However, don’t count copper foil out! Foiled lamps and sculptural pieces can have remarkable durability. And thinner lead came doesn’t necessarily excel over foil. It depends on glass selection, soldering skill, and other reinforcements.

Is Working With Lead Came Dangerous?

Some answer the lead came vs copper foil question based simply on the presumed danger of working with lead. The major health risk with lead came comes from accidental ingestion. However, the metal itself is very stable when left intact. With good work practices, lead came is not inherently hazardous.

That said, we don’t recommend kids or pregnant women handling lead. Be sure to research current health guidelines. Safety steps like washing hands, cleaning up debris, and wearing a dust mask minimize risk. Lead came use is perfectly acceptable for stained glass work with suitable precautions.

Can You Patina Hobby Came?

Absolutely! Hobby came works with patinas just like standard lead came. Patinas create an aged, antique look as metal oxidizes.

Chemical patinas react with the lead or solder to impart color. They can produce anything from burnt red to verdigris green to classic black. Multiple coats blend and add depth.

Alternatively, torching or sanding physically burns the metal. This achieves darker patinas without chemicals. Both approaches work on tiny hobby came. Patinas don’t discriminate based on came size!

Lead Came or Copper Foil?

I’ve covered everything from differences to safety to combining techniques. So which approach reigns supreme in the great lead came vs copper foil debate? As with most artistic endeavors, the answer is it depends!

For longevity, nothing surpasses real lead came. But copper foil offers versatility and expressiveness. Many pieces layer both for maximum impact.

Frequently Asked Questions

How thick is standard lead came?

Standard lead came ranges from 1/8″ to 3/8″ thick. The most common sizes used are 3/16” and 1/4”.

What are the most common lead came shapes besides H and U?

Other common lead came profiles include I, T, and L shapes. These allow flexibility for different glass joining needs.

Does lead came limit the thickness of glass you can use?

Yes, the channel size of lead came determines the glass thickness. Common came suits glass from 2mm to 6mm thick.

Can lead came be used for small delicate pieces?

Lead came can be challenging for petite pieces. Thinner hobby came or copper foil works better for delicate stained glass elements.

Is lead-free came better for marine environments?

Lead-free came avoids lead leaching risks near water. Brass and zinc came are common lead-free choices for marine pieces.

How do you cut copper foil to size?

Foil can be cut with regular scissors or scored and snapped. A special foil cutter tool also quickly sizes foil strips.

What width copper foil is best for stained glass?

3/16” and 7/32” are popular widths. Use wider foil for thicker glass and tighter curves, thinner for delicate work.

Does copper foil come in different colors?

Besides bare copper, foil comes in silver, black, and brass tones. Colored foil suits certain glass colors better.

How do you wrap copper foil in tight spots?

Pointed fid tools push foil into crevices. Foil glue helps adhere in tight areas before soldering.

FAQ Continued . . .

How do you smooth foil seams after soldering?

File down any bumps in the solder line. Finish with increasingly finer grit sandpaper. Buff with a polishing cloth.

Can you use a household iron to attach copper foil?

No, a soldering iron reaches 700-860°F to melt the foil adhesive. A regular iron won’t get hot enough.

How do you keep foil edges from peeking out?

Burnish carefully with a fid tool. Visible edges often mean the foil is not firmly adhered or is undersized.

Is there an easy way to remove excess foil?

Foil scissors easily trim off unwanted overhang. A craft knife also slices excess foil cleanly.

What are the best lead substitutes for came?

Top lead-free choices are zinc, brass, copper, and reinforced copper foil came. Zinc is affordable but hard to work. Brass needs frequent polishing.

Is lead-free came made of pure copper?

Lead-free came contains some copper but isn’t pure. Other metals like zinc or brass are blended in for affordability and workability.

Can you melt lead came scraps into new came strips?

It’s possible but challenging. Precisely re-forming melted lead into thin came is difficult without proper tools.

What are signs that lead came needs replacing?

Look for came with bulging sides from repeated glass removals. Rattling, oxidation, and poor joint seals also indicate deterioration.

How do you clean oxidized lead came?

Use oxalic acid or a mild metal polish. Rinse thoroughly after cleaning came to remove any chemical residue.

Success in stained glass comes down to making choices that get you to your desired outcome. Mastering both methods gives you extensive creative freedom. Whichever route you pick, creating with stained glass is a lesson in patience and passion.